Maximum Corrosion Resistance

Houston’s humid climate accelerates rust and corrosion, making powder coating a must-have for industrial applications. Unlike liquid paint, powder coating creates a uniform, seamless barrier that:

✔ Prevents moisture penetration and rust formation

✔ Resists chemicals, solvents, and industrial contaminants

✔ Offers extended protection for exposed metal surfaces

This is especially crucial for offshore structures, pipeline infrastructure, and industrial plants where exposure to moisture and chemicals is a constant threat.

Extended Equipment & Material Lifespan

Powder-coated metal components last significantly longer than painted alternatives, reducing the need for frequent recoating, repairs, or replacements.

✔ Pipelines & Beams: Powder coating provides a protective barrier against wear and tear from weather and industrial operations.

✔ Scaffolding & Structural Steel: Enhances durability and maintains strength over time.

✔ Heavy Equipment & Machinery Parts: Reduces downtime and extends operational life.

By investing in powder-coated components upfront, contractors can save money on future maintenance and replacement costs.

Superior Impact & Abrasion Resistance

Construction environments are demanding, and powder-coated surfaces can withstand heavy use, abrasions, and impacts better than paint.

✔ Highly durable – Won’t chip or peel under extreme conditions

✔ Ideal for high-traffic areas – Perfect for bridges, industrial flooring, and scaffolding

✔ Long-lasting finish – Retains color and integrity for years

Environmentally Friendly Solution

Powder coating is a low-waste, eco-friendly alternative to traditional liquid paint. Unlike conventional coatings, powder coating:

🌱 Contains zero solvents or VOCs (volatile organic compounds)

🌱 Generates minimal overspray for reduced waste

🌱 Uses a recyclable process, making it more sustainable

For construction companies aiming for LEED-certified or green building standards, powder coating is a superior, environmentally responsible choice.

Custom Finishes & Colors for Industrial Applications

At Houston Powder Coaters, we offer a wide range of coatings designed for industrial durability. Whether you need:

✔ Heat-resistant coatings for pipelines and metal beams

✔ Weatherproof coatings for outdoor infrastructure

✔ Specialty coatings for oil & gas, energy, and heavy construction projects

We provide custom finishes and colors to meet your specific project needs.

Applications of Powder Coating in Construction

Powder coating is the preferred solution for a wide range of industrial and commercial construction applications, including:

✔ Structural steel & beams – Bridges, buildings, and infrastructure projects

✔ Pipelines & gas lines – Long-term protection against rust and erosion

✔ Scaffolding & safety railings – Ensures durability and safety compliance

✔ HVAC & ventilation systems – Reduces maintenance and improves efficiency

✔ Metal staircases & fencing – Aesthetic, durable finishes for commercial properties

Why Houston Powder Coaters?

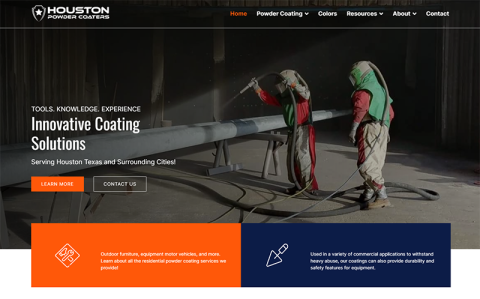

At Houston Powder Coaters, we are one of the leading powder coating operations in Texas, serving Houston and the entire Gulf Coast region.

✔ Industrial-Grade Durability – Built to withstand Houston’s harshest conditions

✔ Large-Scale Capability – We handle high-volume orders for major construction projects

✔ Fast Turnaround – Keep your projects on schedule with quick processing and delivery

✔ Expert Technicians – Decades of experience in industrial powder coating solutions

📞 Need high-performance powder coating for your construction project? Contact us at (281) 676-3888 or visit houstonpowdercoaters.com for a free consultation!