Marine Coatings

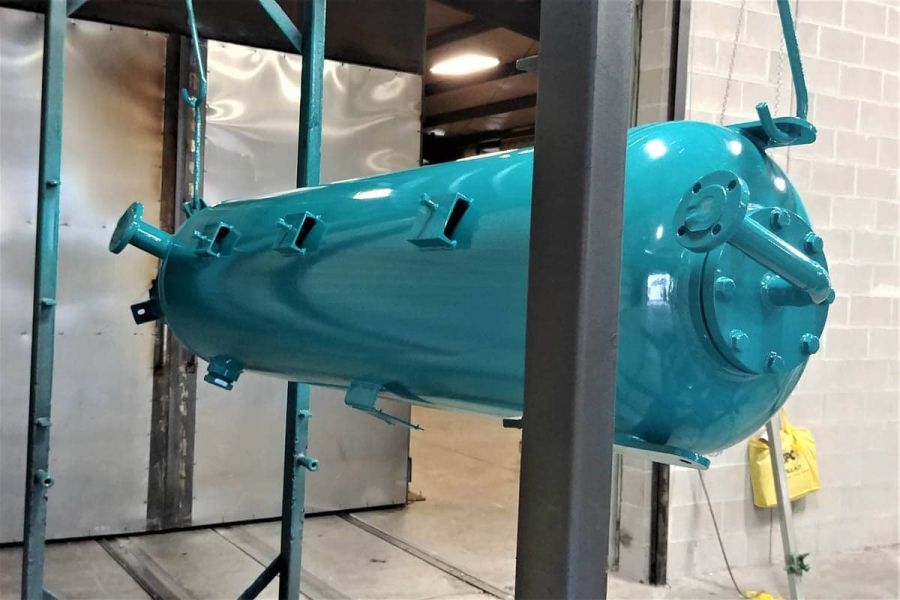

Marine coating applications must stand up to the harsh saltwater environments of southeast Texas and the Gulf of Mexico. The sun, the waves, and the storms combine to ruin any decorative finish, by corroding parts above and below deck. Houston Powder Coaters will help extend the life and look of your boat by refinishing T-tops, leaning posts, railings, swim platforms, extrusions, and more.

To remove the oxidation on weather-beaten aluminum pieces, HPC will abrasive-blast or hand-etch each part, ensuring a clean surface from which to coat. After preheated to allow for outgassing, the pieces will then undergo a thick application of powder to build-up a protective barrier to guard against future salt and spray. Once in the oven, the powder will fusion-bond with the metal to ensure a durable yet elegant finish. With a variety of colors, glosses, textures, and effects to choose from, you can match your current equipment or achieve a fresh look.