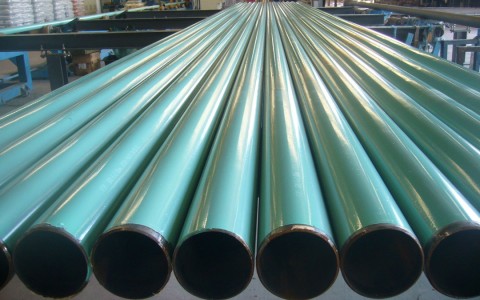

The industrial coating used to protect the pipes we use every day is not something that most people think about with any frequency. After all, most of us are too busy working and taking care of our loved ones to sit around and have deep thoughts about the pipes that deliver the fuel which powers our vehicles, bring clean water into our homes, and remove dangerous waste and sanitation. However, it’s clear that these are all aspects of modern living that society heavily depends on. Without pipelines moving fluids, many modern conveniences would be impossible, and therefore the protection of these conduits is not to be overlooked. Although many people are aware, few are familiar with the processes and materials used to protect the pipes that make their modern lives possible, such as corrosion resistant industrial coatings.

Among the various types of industrial coatings Houston, corrosion resistant coatings are some of the most common yet crucial. For the ever-important oil and gas industry here in Texas and the rest of the country, treating pipeline to be resistant to corrosion is a fact of life. According to the National Association of Corrosion Engineers, the cost of corrosion in petroleum refining is $3.7 billion in the U.S. annually—that’s a lot of money lost down the pipes due to mostly preventable chemical processes. The chemicals flowing through pipeline, as well as the high flow rate and volume of fluid, contributes to heavy corrosion across the industry. Recent increases in shale gas production have also offered new challenges in protecting pipeline.

There are multiple methods of corrosion prevention used in industrial applications, though its usage varies by the setting, environment, and type of material to be protected. Cathodic protection, commonly used in both onshore and offshore drilling operations, is one method of corrosion prevention which utilizes electromagnetism and chemistry to protect pipe. Corrosion inhibitors are also frequently used in the industry; these chemicals coat the surface of the pipe to form a protective film which then reacts with the corrosion-causing chemicals and interrupt the process. Among industrial coatings Houston, fusion bonded epoxy (FBE) has made significant gains in popularity. FBE is a powder-based coating which uses high temperatures to form interlocking chemical protection that is highly effective in protecting pipe and has seen increasingly widespread adoption as a protection method.