Fusion Bonded Epoxy Coatings

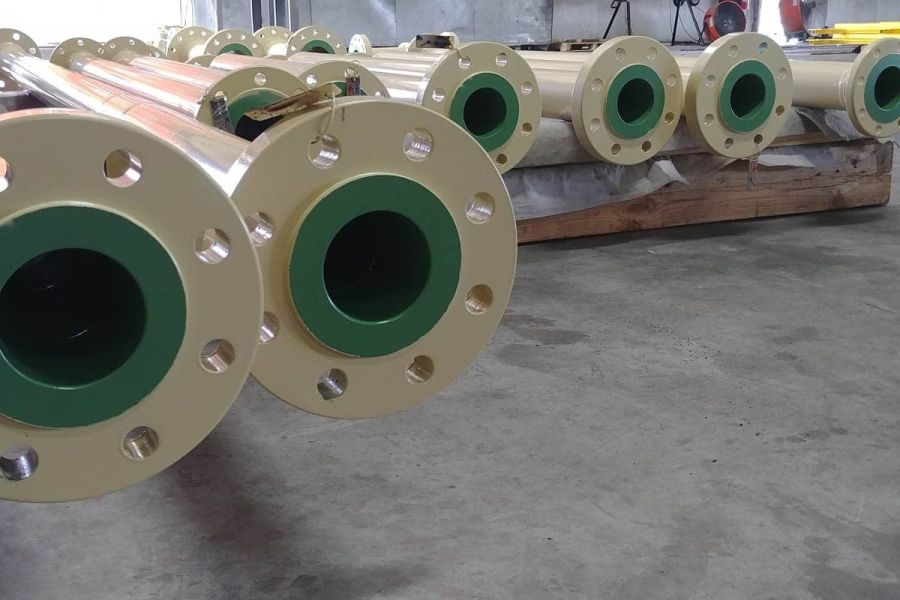

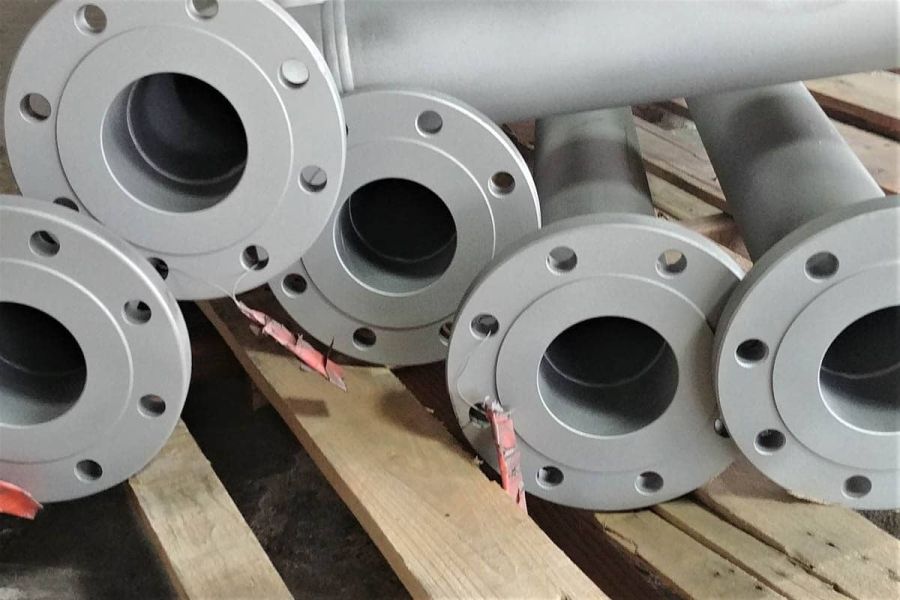

Houston Powder Coaters offers a triple-application high-performance coating system designed for internal and external pipe surfaces. With a combination of corrosion and chemical resistant properties required in high temperature and elevated pressure environments, this protective coating system also achieves optimal levels of strength and flexibility to minimize wear and fatigue. Furthermore, the combined applications provide a smooth and consistent finish that allows for reduced frictional drag and enhanced flow dynamics. This in turn diminishes the effects of shear dispersion and molecular diffusion resulting in improved paraffin mitigation.

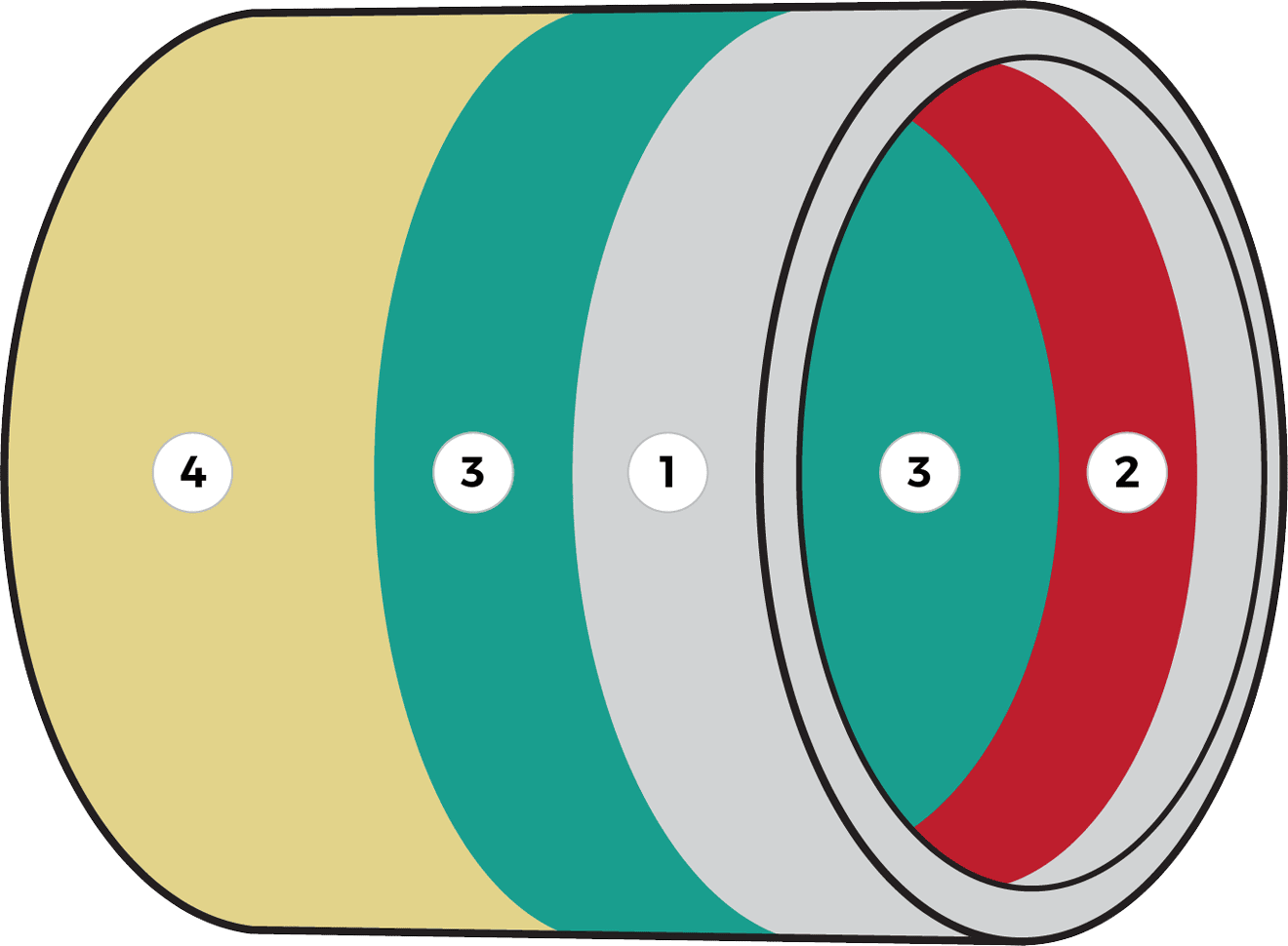

Interior / Internal Coatings

The phenolic primer is preparatory anti-corrosive basecoat that greatly inhibits corrosion in oxygenated atmospheres. Furthermore, this thin layered protective coating is resistant to CO2, H2S, CH4, brine, and petroleum distillates at elevated temperatures and pressures, making it a preferred choice of engineers and operators.

The second internal pipe coating is a fusion bonded epoxy that allows for a higher level of thickness to be obtained in single pass processing. Through its chemical cross-linking, the thermoset polymers create a hardened finish that is not only chemical resistant, but abrasion resistant.

Exterior / External Coatings

As the curative properties of the fusion bonded epoxy allows for a thicker build-up of protective resin and hardener components, this external basecoat interlaces with the metal substrates’ anchor profile to create a hardened shell that greatly outperforms other coating systems.

Finally, a fusion bonded high-performance polyester is applied sealing the base coatings resulting in improved weatherability and UV degradation protection.

Features and Applications

The Benefits of Fusion Bonded Coatings Are Clear

Features

- Excellent Chemical Resistance

- Excellent Co2, Ch4, And H2s Resistance

- Excellent Surface Adhesion

- Operational At High Pressures & Temperatures

Suitable Applications

- Piping, Flanges, Manifolds, Fittings, Couplings

- Upstream & Downstream Pipe & Tubing

- Ambient To High Pressure/Temp Requirements

- Oil & Gas, Water, Sewage Lines