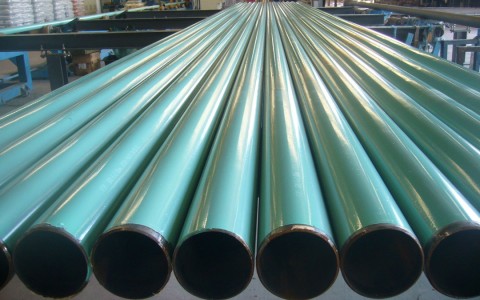

Fusion bonded epoxy (FBE for short) and abrasion resistant overcoat (ARO for short) are well known in Houston for their uses in the oil and gas industry. Where they are not well known, however, is in the municipal water industry, such as pipes used to bring drinking water into our homes and sewage pipes and at water treatment plants. The municipal water industry is due for a big upgrade in the next few years. Using fusion bonded epoxy and abrasion resistant overcoats to protect pipes from corrosion will ensure the longevity of the pipes and the health and safety of the region’s residents. Water pipelines can be lined with cement after FBE/ARO applications.

FBE became commercially available in the 1960s, and in the decades since has become a true competitor in the industry for coatings to protect steel pipes and more for the oil and gas industry. It offers great corrosion protection and is environmentally friendly as it involves no solvents. This lack of solvents makes FBE in Houston the perfect option for the municipal water industry. When it comes to drinking water, you have to be careful that the pipes will not leech anything into the water that is hazardous to the health of residents. Typically, pipes are lined with cement mortar and spun at a high rate of speed to compact the mortar to the interior of the pipes. FBE, in combination with ARO coatings, exceeds many standards and requirements for potable water, and the corrosion protection is second to none.