Essential Pre-Treatment Advice For Powder Coating Aluminum In Houston

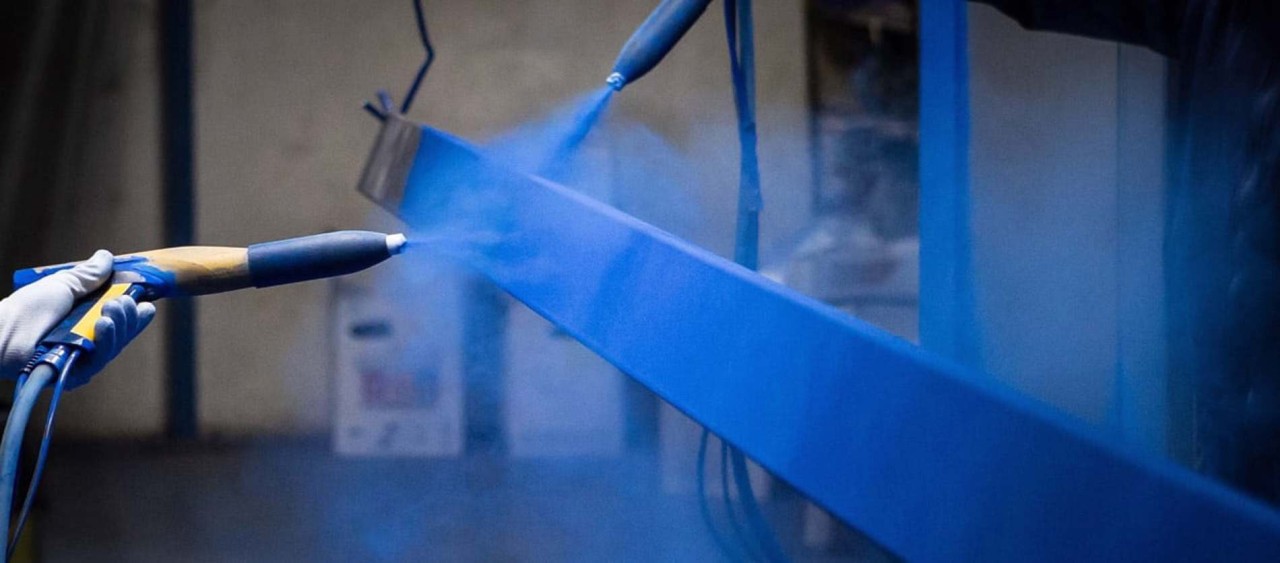

Powder coating is a great option to coat metals like aluminum and protect them from a harsh environment. The powder coating method ensures a durable, long-lasting finish that is environmentally friendly and cost-effective. However, to get the durability you expect out of powder coated aluminum, pre-treatments are necessary to make an optimum surface for the powder coating to stick to.

The first step in pre-treatment of aluminum for powder coating is degreasing. The method of degreasing for the aluminum will depend entirely on the surface of the metal and the pollutants involved. The three primary methods of degreasing aluminum for powder coating are solvent cleaning, vapor cleaning, and emulsion cleaning. Solvent cleaning is the best method if you need to preserve the surface of the metal. Heavy grease and oil are removed from the surface using a solvent-soaked cloth and wiping the surface clean. Emulsion cleaning and alkali cleaning use a solvent with a higher pH and a dipping method. The metal is dipped in the solvent for a few minutes, removed, and rinsed.

Removing rust is the second pre-treatment step for powder coating aluminum in Houston. Corrosion is a major weakness for metal, and the whole reason behind powder coating is to prevent corrosion. However, that doesn’t mean a surface is ruined if rust is present. It can be removed and then powder coated to further protect the metal from further corrosion. Rust is easily dissolved with acid, so this pre-treatment step is relatively simple. This method will also require a rinse afterward.

Next are two things called “activation” and “conversion.” These two steps involve an extra coating on the aluminum to prevent further oxidation. A chromium phosphate coating or a chromate coating are both appropriate for aluminum.

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.