Used across a variety of industrial and commercial applications, steel is one of the most common construction materials used in the world today. As one might expect, its integrity is of the utmost importance when the metal is part of an erected assembly that cannot be “undone.” Whether the steel is for bridges, light towers, or even the fire suppression systems integrated in every building, corrosion protection is paramount to ensure the longevity, dependability, and integrity of the metal substrate. Although there are multiple types of corrosion protection in the industry, one that sets itself apart is a duplex system of Powder Coating over Hot-Dipped Galvanized Steel. This double system of coatings ensures an impact-resistant, chemical-resistant, and corrosion-resistant formula that looks good as well.

Developed as a method for preventing corrosive agents from reaching the base metal, galvanizing is the process of dipping steel in a bath of molten zinc. Originated in 1742, galvanization has evolved over hundreds of years resulting in better application, adherence, and longevity standards.

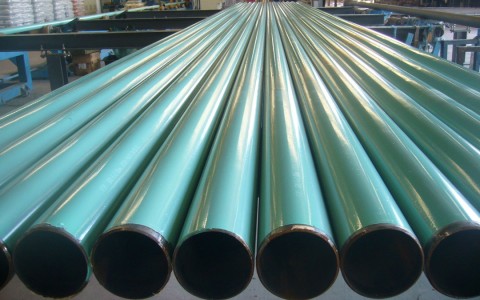

Powder Coating over Hot-Dipped Galvanized Steel is the second phase of this resilient duplex system. Unlike its traditional wet-paint counterpart, powder coating takes advantage of its electrochemical bonds to sink deeper into the anchor profiles thereby creating a hardened shell. Hot-dip galvanizing provides the basic cathodic and barrier protection underneath while the powder coating handles the chemical, impact, and corrosive resistance on top.